Between September and November 2022, we worked closely with a team of six Engineering Masters students from Delft University of Technology in the Netherlands alongside our project partner Boskalis Westminster to investigate the upscale potential of seagrass restoration in the Solent.

Esmee Menting – MSc Mechanical Engineering, Delft University of Technology:

Our aim was to (re)design the process or tools in order to increase capacity of reseeding seagrass meadows in the Solent by 300% within two years. We started by analysing the current restoration process applied in the Solent, as well as restoration techniques implemented in other seagrass restoration projects worldwide.

When reviewing the available literature, it became clear that the success of restoration methods is extremely bound to the local ecosystem and conditions. This leads to an elaborate trial-and-error process that must take place for nearly all restoration projects to establish a fruitful process. Resulting restoration success can be quantified and evaluated by the germination rate; how many seedlings appear per planted seed, per deployment method.

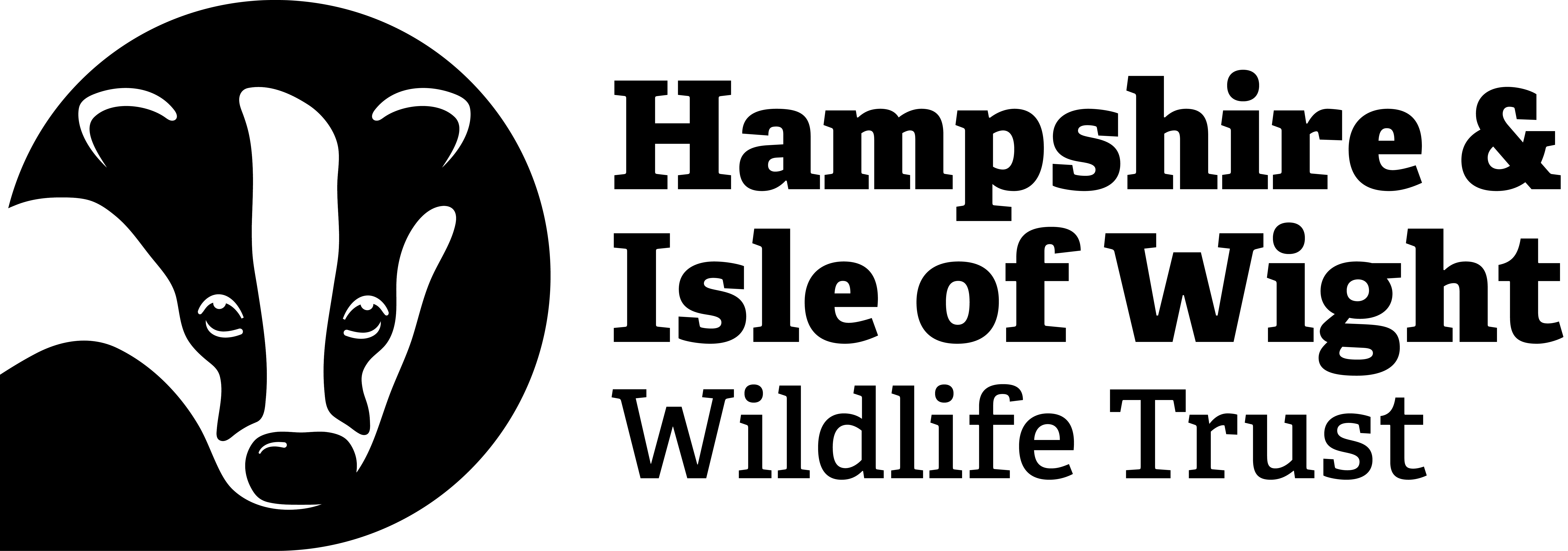

The reseeding process that is applied in the Solent can be split up into five phases; (1) the collection of spathes, (2) rotting out of plant material (releasing seagrass seeds), (3) filtering seeds from the plant material, (4) packaging the seeds and (5) deploying the seed pods or packages.

As a team, we identified two critical points in the current process of the Solent restoration effort:

-

The filtration of viable seeds from the plant material is an incredibly time-consuming process step, due to its heavy reliance on manual processing.

-

The deployment of seed (packages) is labour-intensive and might strongly influence the germination rate and thus overall success of a restoration effort.